What is Polypropylene Glycol?

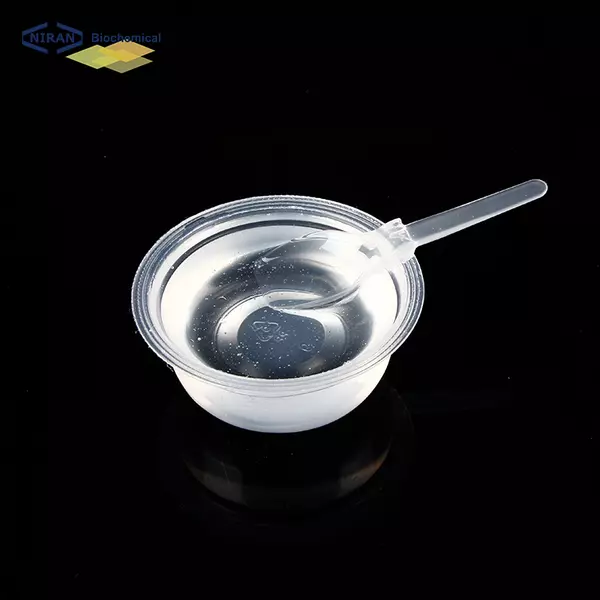

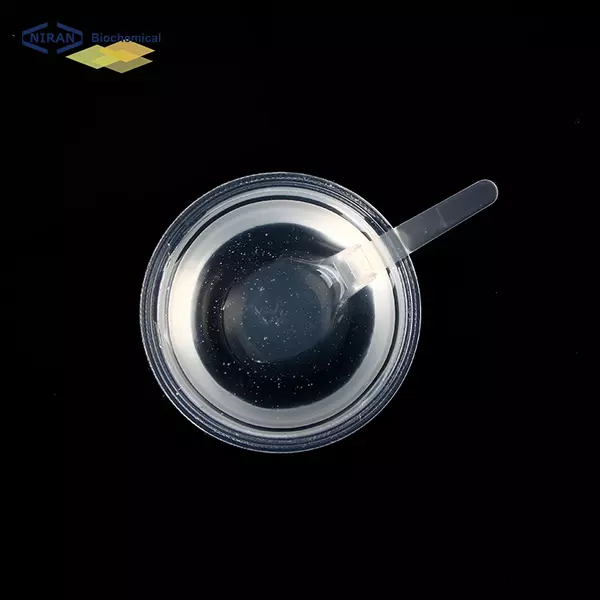

Polypropylene glycol is an organic polymer that appears as a white or transparent liquid and is non-volatile. In the food business, it is frequently utilized as a solvent, emulsifier, and stabilizer because it is non-corrosive. It can effectively improve the texture and stability of food, prevent the separation of ingredients, and provide uniform mixing and handling performance during processing.

In addition, PPG is also used as a lubricant and moisturizer in medicines and cosmetics to improve the performance and stability of products.

The preparation processes of polypropylene glycol in China are mainly as follows:

- Polymerization reaction method: This is the most mainstream process. Propylene oxide is polymerized under the action of a catalyst to generate PPG with different molecular weights. This method can effectively control the reaction conditions and produce high-purity food-grade PPG.

- Hydrogenation method: It is mainly used to adjust the properties and stability of PPG, and generate polypropylene alcohol by hydrogenating propylene oxide. This method can adjust the molecular weight and performance during the production process, and requires refining treatment to ensure the food grade standard of the product.

Related parameters:

| Specifications | Appearance

(25°C) |

Color and lustre

Pt-Co |

Hydroxyl value

mgKOH/g |

Molecular weight | Acid value

mgKOH/g |

Water

(%) |

PH(1% water solution) |

| PPG-200 | Colorless transparent oily viscous liquid | ≤20 | 510~623 | 180~220 | ≤0.5 | ≤0.5 | 5.0~7.0 |

| PPG-400 | Colorless transparent oily viscous liquid | ≤20 | 255~312 | 360~440 | ≤0.5 | ≤0.5 | 5.0~7.0 |

| PPG-600 | Colorless transparent oily viscous liquid | ≤20 | 170~208 | 540~660 | ≤0.5 | ≤0.5 | 5.0~7.0 |

| PPG-1000 | Colorless transparent oily viscous liquid | ≤20 | 102~125 | 900~1100 | ≤0.5 | ≤0.5 | 5.0~7.0 |

| PPG-1500 | Colorless transparent oily viscous liquid | ≤20 | 68~83 | 1350~1650 | ≤0.5 | ≤0.5 | 5.0~7.0 |

| PPG-2000 | Colorless transparent oily viscous liquid | ≤20 | 51~62 | 1800~2200 | ≤0.5 | ≤0.5 | 5.0~7.0 |

| PPG-3000 | Colorless transparent oily viscous liquid | ≤20 | 34~42 | 2700~3300 | ≤0.5 | ≤0.5 | 5.0~7.0 |

| PPG-4000 | Colorless transparent oily viscous liquid | ≤20 | 26~30 | 3700~4300 | ≤0.5 | ≤0.5 | 5.0~7.0 |

| PPG-6000 | Colorless transparent oily viscous liquid | ≤20 | 17~20.7 | 5400~6600 | ≤0.5 | ≤0.5 | 5.0~7.0 |

| PPG-8000 | Colorless transparent oily viscous liquid | ≤20 | 12.7~15 | 7200~8800 | ≤0.5 | ≤0.5 | 5.0~7.0 |

Recommended dosage:

| Food name | Maximum usage(g/kg) |

| Candy | 0.5-1.0 g/kg |

| Chocolate | 0.5-1.0 g/kg |

| Ice cream | 0.5-1.0 g/kg |

| Condiments | 0.5-1.0 g/kg |

| Salad dressing | 0.5-1.0 g/kg |

| Protein bars | 0.5-1.0 g/kg |

| Cheese | 0.5-1.0 g/kg |

| Pudding | 0.5-1.0 g/kg |

| Jelly | 0.5-1.0 g/kg |

| Coffee creamer | 0.5-1.0 g/kg |

| Sauces | 0.5-1.0 g/kg |

| Preserved foods | 0.5-1.0 g/kg |

| Fruit drinks | 0.5-1.0 g/kg |

| Energy drinks | 0.5-1.0 g/kg |

| Beer | 0.1-0.5 g/kg |

Polypropylene Glycol has a wide range of uses

- Emulsifier and stabilizer:

PPG as an emulsifier and stabilizer can help oil and water mix evenly to form a stable emulsion. This is very important in many foods, such as condiments and dairy products, where PPG can prevent the separation of ingredients and maintain the uniformity and consistency of food. - Improve texture:

PPG can improve the texture and taste of food. In products such as candy, chocolate and ice cream, PPG helps provide a smoother texture, making the product softer and easier to handle. - Extend shelf life:

PPG has good stability and can reduce water evaporation and oxidation in food, extending the shelf life of food.This keeps food from spoiling and preserves its freshness and quality. - Lubricant:

In food processing, PPG as a lubricant can reduce the adhesion of ingredients and improve the operability and cleanliness of production equipment. This increases production process efficiency and reduces equipment maintenance costs.

User asked question:

Q: What is the difference between polypropylene glycol and glyceryl monostearate?

A: Polypropylene glycol (PPG) and glyceryl monostearate (GMS) are two food additives with different functions. PPG is a viscous liquid, mainly used as an emulsifier, stabilizer and lubricant, and is widely used in foods such as candy, chocolate, ice cream, etc. to improve texture and extend shelf life.

GMS is a solid or semi-solid emulsifier, mainly used in baked goods, dairy products and ice cream, to help form a stable emulsion and improve the texture of food.

PPG is usually added in liquid form and can be dissolved in water and organic solvents, while GMS exists in solid form and needs to be dissolved and emulsified during processing.

-300x300.webp)

-300x300.webp)